America’s southern ports of entry — long the principal gateway for illegal drugs — will be getting more technology in 2020.

The federal government has awarded a Massachusetts company a contract to install four undercarriage X-ray scanners at two South Texas ports of entry early next year.

In addition, U.S. Customs and Border Protection (CBP) is testing non-intrusive inspection (NII) at four border crossings and has a Congressionally authorized war chest of half a billion dollars to spend on the right technologies, federal lawmakers, CBP officials and private contractors are telling Border Report.

“Drive-through technology is being piloted“

“Drive-through technology is being piloted in Brownsville (Texas), it does seem promising. There are several ports — not only the port of Brownsville — but Hidalgo, the port of Progreso and perhaps even the port of Laredo –that are trying different systems, particularly the drive-through systems, to see if they meet our needs,” El Paso port of entry Director Hector Mancha said earlier this month.

Agents at border crossings for the past couple of decades have been utilizing technology such as VACIS (vehicle and cargo inspection systems), mobile tractor-truck X-ray systems and stationary gamma-ray machines. But the inspections are time-consuming and only 15% of commercial trucks and 1% of private vehicles coming into the United States are scanned, Texas and New Mexico lawmakers say.

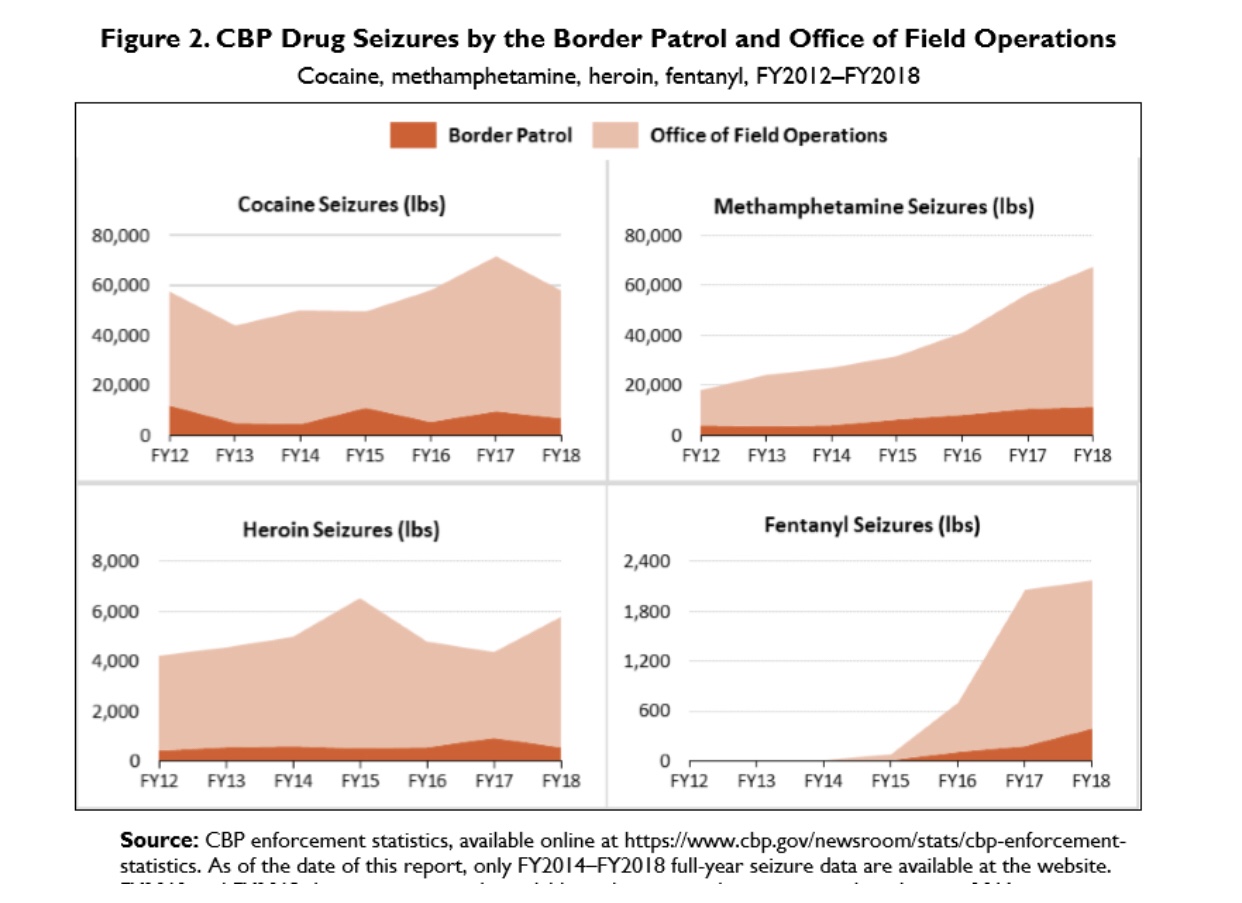

Mexican drug cartels like those odds and continue to send loads of cocaine, heroin, fentanyl and methamphetamine through the ports of entry. According to a July 3 report by the Congressional Research Service, 65% of all illegal drug seizures made since 2012 at the border occured at Southwest ports of entry where thousdands of trucks and regular vehicles cross into the U.S. every day.

That combination is pushing lawmakers like Dan Crenshaw, R-Texas, a former Navy seal, to insist on arming CBP with technology to enable officers to inspect more trucks and cars more quickly.

“We’ve got this pilot program going on in Texas where vehicles just drive through. It can drastically reduce the time it takes for Customs to actuallly see what’s in those vehicles to make sure they’re safe for entry into the United States and get commerce moving,” Crenshaw said.

He expects the pilot programs “should be wrapping up soon” and then it’ll be time for federal agencies to make recommendations on which are effective.

Mancha said CBP agents already in 2019 performed 6.6 million NII scans that led to the seizure of 216,203 pounds of drugs, $3 million in undeclared currency, 1,655 guns and 200 unauthorized migrants hiding in cargo trucks.

‘It’s like an instant X-ray’

X-ray imaging technology is used on a daily basis at Southwest ports of entry, but typically only when an inspector sends a truck or a passenger vehicle to what is known as “secondary inspection.”

The existing devices are large, there are not enough of them and each inspection can last up to 8 minutes, according to lawmakers.

But new, “game-changing” technologies are now on the market, and the federal government is starting to acquire them for CBP.

Viken Detection of Burlington, Mass., had been providing handheld X-ray scanners known as the HBI-120 to CBP and to various law-enforcement agencies before it was awarded a contract recently for new undercarriage X-ray scanners known as Osprey-UVX.

“When a car drives over the system, the Osprey-UVX allows them to see through the undercarriage of a vehicle safely in under one minute. The undercarriage is a common hiding spot for drugs and other contraband, yet until now there wasn’t a way to reliably search it,” said Jim Ryan, CEO of Viken Detection.

The system is designed for border crossings with high volumes of traffic. Passengers stay in the vehicle and there’s no threat to their safety while an image is generated for the CBP agent that will be inspecting their documents, vehicle and belongings.

comprehensive” plan to test and deploy large-scale NII equipment at border crossings in 2020 and points to bills like the Securing America’s Ports of Entry Act (co-sponsored by Crenshaw) as further commitments to improve border security.

“After meeting with CBP and House committees on homeland security … I believe everyone is in agreement that we desperately need this equipment at the border,” Ryan said. “With coordination, communication and a concerted effort to streamline the funding process, I believe tremendous progress can and will be made in 2020.”

It has been a historic decade for the global logistics industry. The market has grown tremendously over the years and there have been significant improvements in logistics infrastructure worldwide; thanks to digitization and groundbreaking solutions in supply chain and logistics.

Technological advancements have strengthened the capabilities and functioning of every element of logistics, right from packaging and labeling to shipment, transportation and last-mile delivery. Changes in consumer demands, the rise of e-commerce and fierce market competition have also enabled a rapid transformation of the industry.

The era of smarter and faster logistics has just begun. The industry is poised for massive growth and is expected to reach $12,256 billion by 2022. Today, efficient logistics is not just an added advantage for companies, but a key differentiator and growth enabler in the supply chain. As we enter the new decade, we will see a number of trends that will shape the future of logistics in 2020 and beyond.

Artificial Intelligence

Artificial intelligence (AI) is bringing about a revolution in the way packages move around the world. Many businesses have started implementing AI in their logistics operations to improve speed, enhance supply chain productivity and curb operating costs. In 2020, and the coming years, AI will continue to redefine the world of logistics with innovative offerings such as machine learning algorithms, advanced geocoding abilities, route optimization, demand prediction, warehouse automation and more.

Real-Time Visibility in Supply Chain

Supply chains are multilayered and traditional logistics have a number of blind spots. As cross-border trades increase and online selling continues to grow, old-school logistics systems are not enough to keep a track of goods as they move within the supply chain. Technology is eliminating these blind spots by bringing transparency and visibility at every stage of the supply chain, right from the point of manufacture to warehousing, transportation and delivery.

More and more businesses are now realizing the need to adopt smart tech in order to track the movement of goods. Real-time freight tracking software, active tracking devices, sensors and location-based intelligence will dominate the logistics industry in the near future, enhancing supply chain visibility and improving customer experiences phenomenally.

Supply Chain Digital Twin

The concept of a digital twin has been around for some time now. Typically, a digital twin is a virtual replica of a real-world business process, model or function. In today’s dynamic and highly competitive supply chain landscape, network optimization is the way to go.

With the help of a digital twin, enterprises in the supply chain can plan delivery routes and networks efficiently, prepare for problems before they even occur, speed up operations, and even plan activities for the future. In the coming years, digital twin technology will play a major role in modeling new-age supply chains and streamlining logistics operations effectively with maximum accuracy and minimum wastage.

3PL Collaboration

If supply chains were not complex enough, the era of express deliveries is here to make it more complex. More than 40 per cent of shipments are same-day deliveries today compared with less than 5 per cent four years back. Convenience is the new king and the demand for time-defined deliveries and tracking shipments is pushing supply chain enterprises to partner with 3PL service providers and tech start-ups for efficient warehousing, packaging, shipping and last-mile distribution.

Green Logistics

Traditional logistics systems contribute majorly to carbon emissions and the disposal of toxic and hazardous waste materials. Modern supply chain enterprises must adopt environmentally responsible and sustainable processes to help minimize the ecological impact of traditional logistics operations. In the coming years, companies worldwide will adopt green logistics.

Some green logistics initiatives that are already being implemented by supply chain businesses are sourcing from environmentally responsible partners, reducing energy consumption in transportation, reusing and recycling durable packaging materials.

Digitization and technology advancements will continue to redefine the supply chain and logistics landscape in 2020 and the years to come, streamlining every activity and transforming the way goods travel worldwide.

Source: Entrepreneur

HAPPY BIRTHDAY AEO: 20 YEARS TODAY

It was 20 years ago today, on January 1st 2000, when Sweden launched the operational pilot of the Stairway Concept (Servicetrappan).

This was the first Authorised Economic Operator (AEO) and Trusted Trader programme in the world.

IKEA was the first AEO company, then came AKSO Nobel. KGH was one of the first ten pilots and certified companies of the Stairway programme. In total 40 companies participated in the developments and tests.

Now more than 100 countries worldwide have introduced AEO and Trusted Trader programmes and 100.000 companies are qualified for a certified status. Today we celebrate this historic day.

20 years ago today we had thoughts and new ideas about how we could conduct the central government’s core business, in this case the Swedish Customs Administration.

Today, the Stairwa, under its international name, Authorized Economic Operators (AEO) is a leading international standard for trade, introduced in more than 100 countries worldwide – and with more than 100,000 companies quality assured and validated as low-risk companies, Trusted Traders. The results are overwhelmingly positive.

In Brazil, where AEO was introduced in 2014-2017, an independent academic macroeconomic study has recently been conducted showing that AEO companies have already saved $ 1.5 billion and that Brazil’s economy will grow by $ 17 billion to 2030 thanks to the introduction of AEO in Brazil. Money that can be used to build the nations education system, healthcare and social developments.

Today, this Swedish innovation celebrates 20 years. I feel proud to have been on this journey from day one. After the development of the first model in Sweden, I worked on developing the international standard for the area, the World Customs Organization’s (WCO) SAFE Framework, and I have had the privilege of working with the development and implementation of AEO programs in more than 50 countries.

In March, WCO will host its fifth global AEO conference on in the Dubai and it is expected that more than 2,500 participants from 150 countries will participate.

I get the pleasure to yet another time talk to people from all around the world about the ‘baby’ who was once born in a conference room at Sturup Airport in 1998. A ‘baby’ that no longer crawls, or walks – but runs like a bureaucratic Usain Bolt across the world. One becomes humbly grateful for all the learning included in this 20 year journey.

There are people who say it is difficult to change how government works.

But nothing is impossible.

As Robert Kennedy once said:

“Some men see things as they are and say Why? I dream things that never were and say Why Not?”

You must be logged in to post a comment.